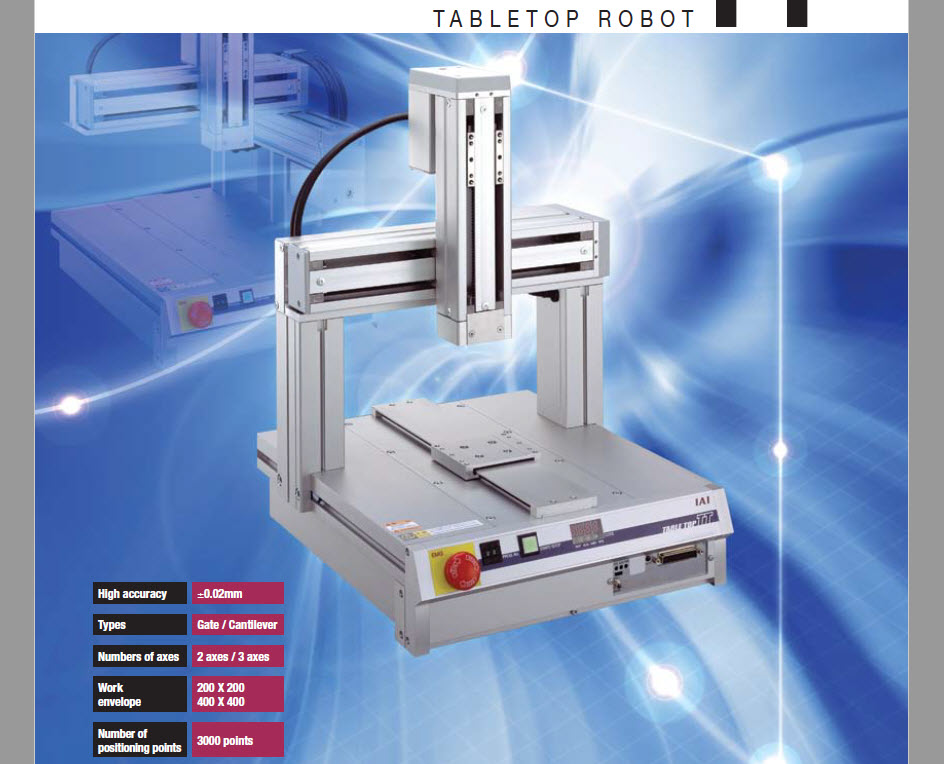

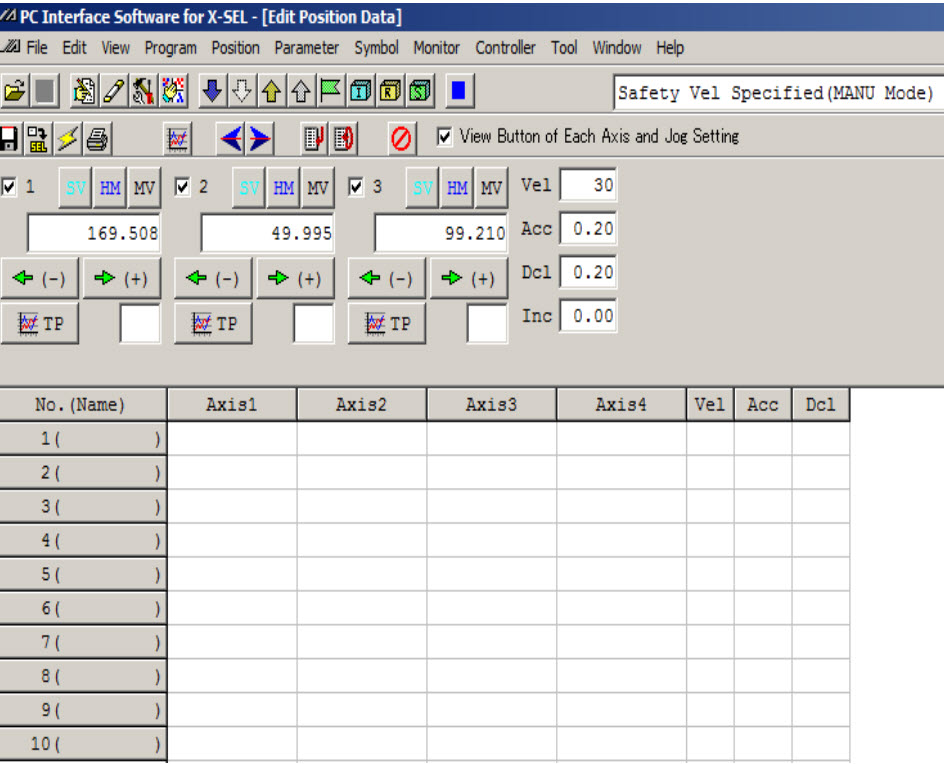

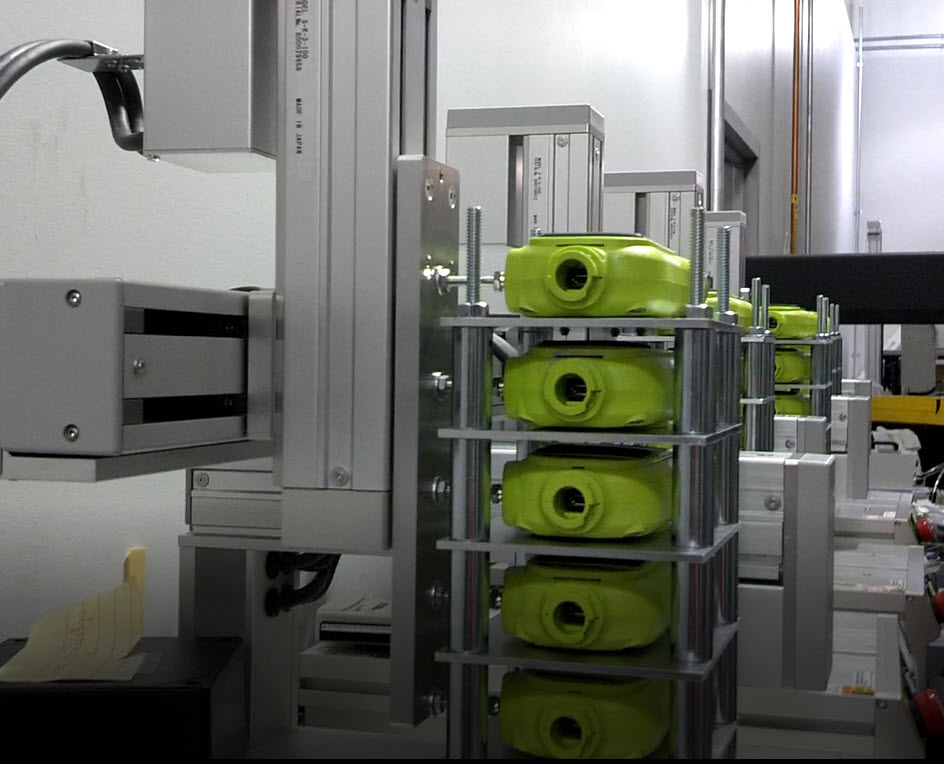

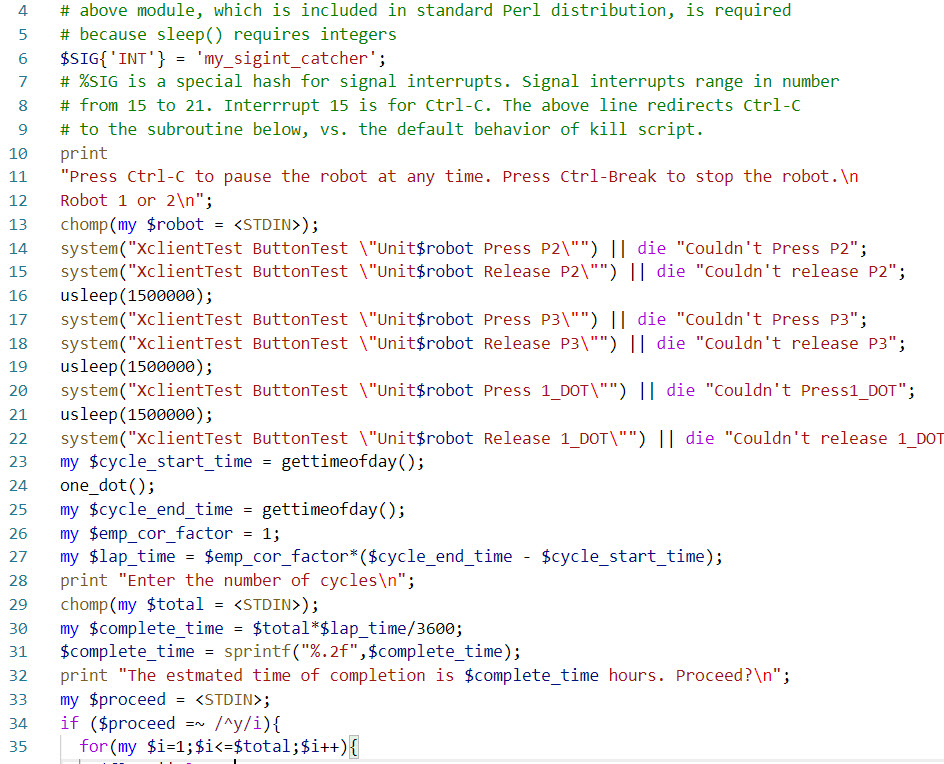

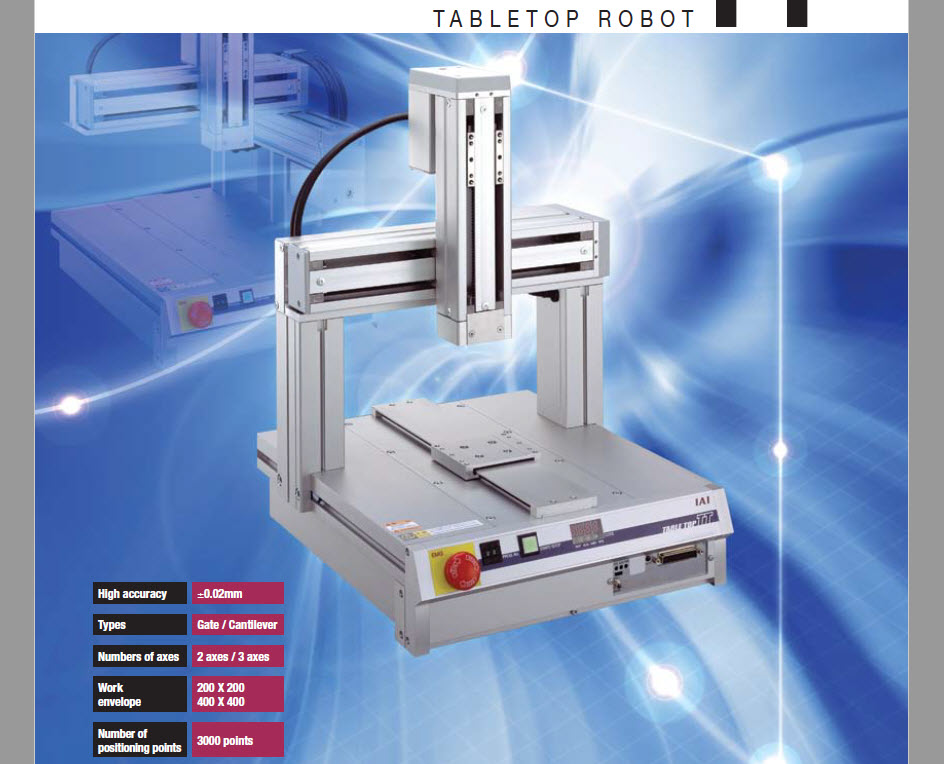

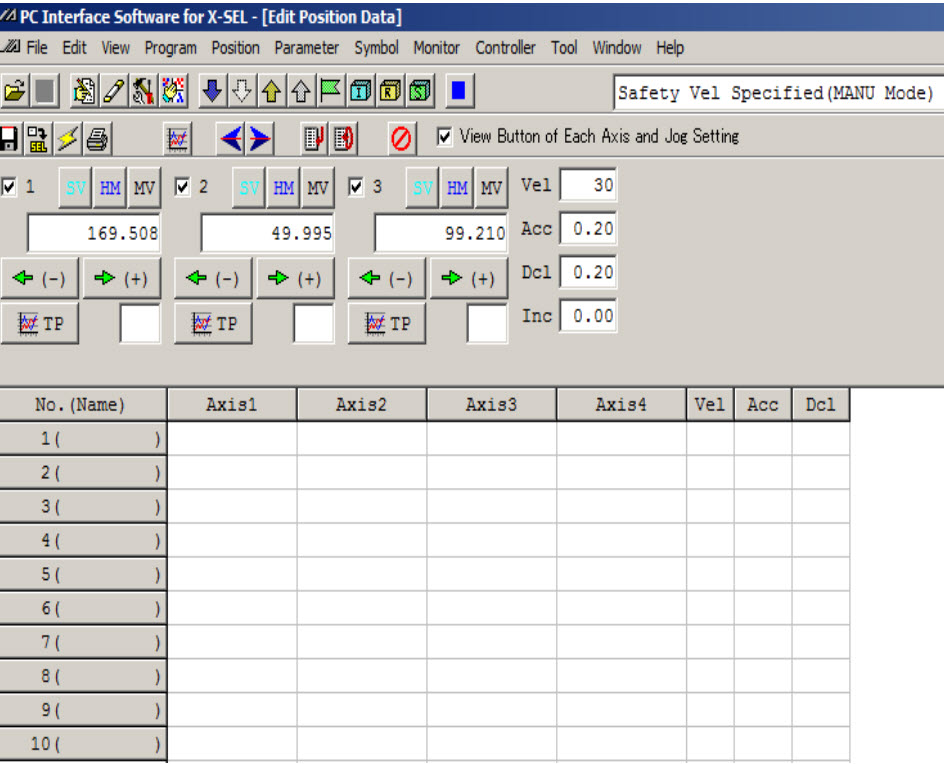

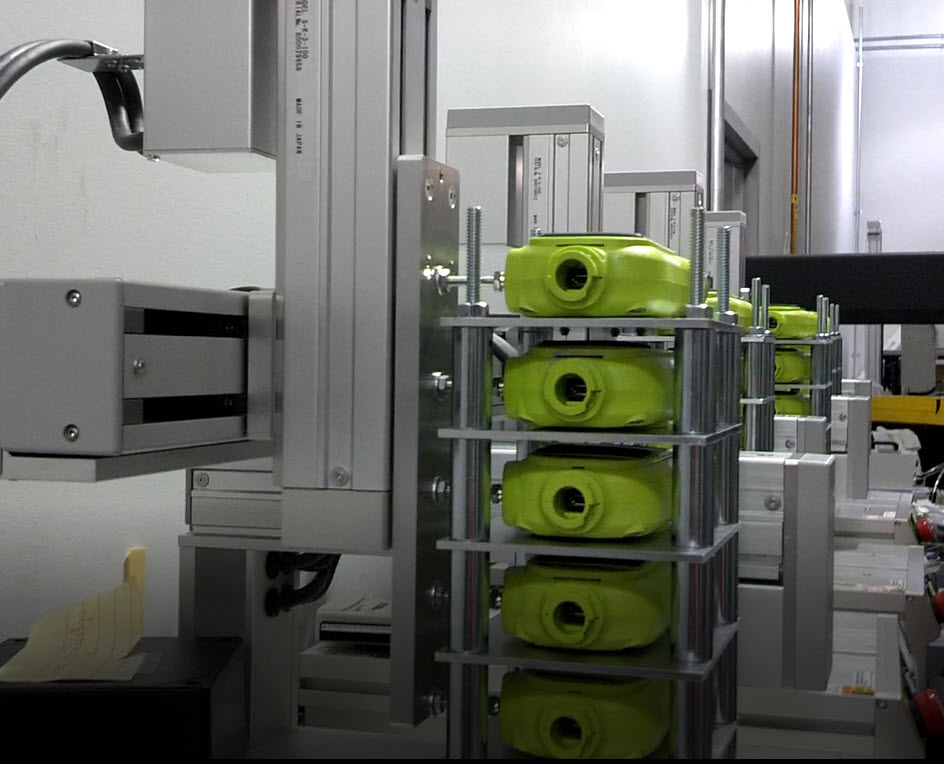

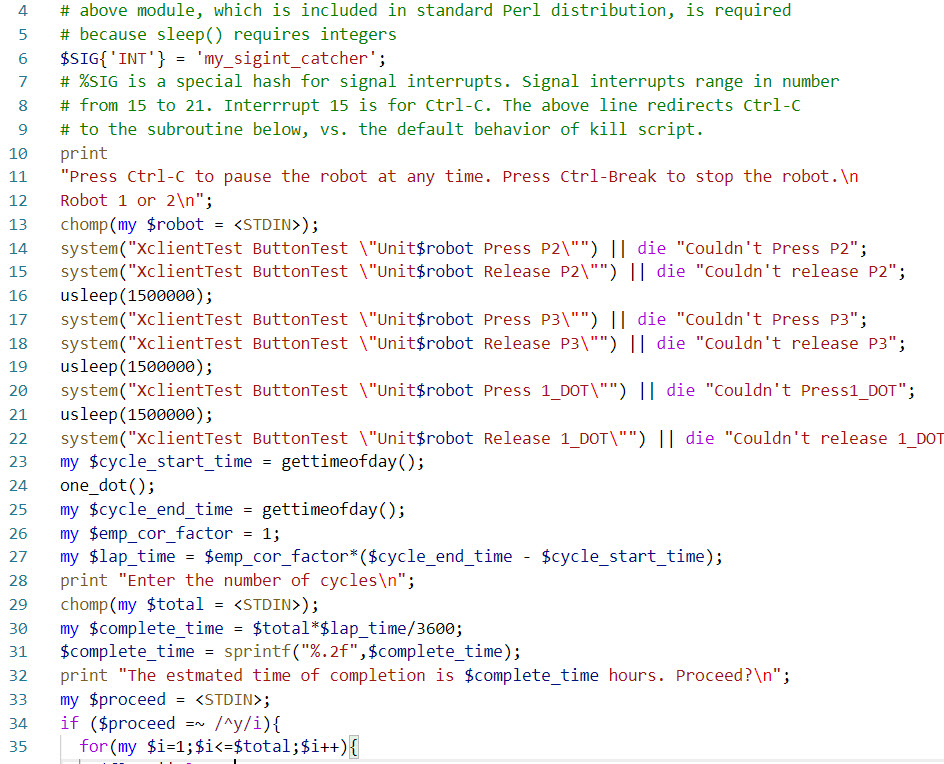

A button design flaw found in a shipping product could seriously compromise the functionality of public safety communications network. This flaw constituted a product recall risk, and the device manufacturing was paused. However, if thirty devices were button on/off cycled 500,000 times each without failure, management would conclude that a recall was not necessary and device manufacturing could resume. In less than one week, FTP designed fixtures, coordinated fixture manufacturing, programmed robots, and validated test fixture functionality. Six robots, each with five devices under test (DUT), ran simultaneously, including one robot and its five DUTs that operated in a 40 C temperature chamber. A total of 15 million button on/off cycles were completed in four days. All DUTs passed, therefore a product recall was deemed unnecessary and device manufacturing resumed.